Home - About Us - Blogs/news - How to choose & determine plastic resin materials for your plastic molding product project?

In today's market, there are tons of material for customer to choose from. Therefore, The selection process of plastic injection molding resin materials is very challenging at the beginning. At Best times mould & plastic products technology Ltd., we are well aware that each plastic resin materials has its unique characteristics and advantages, so we work closely with our customers to choose the suitable materials for their production projects.

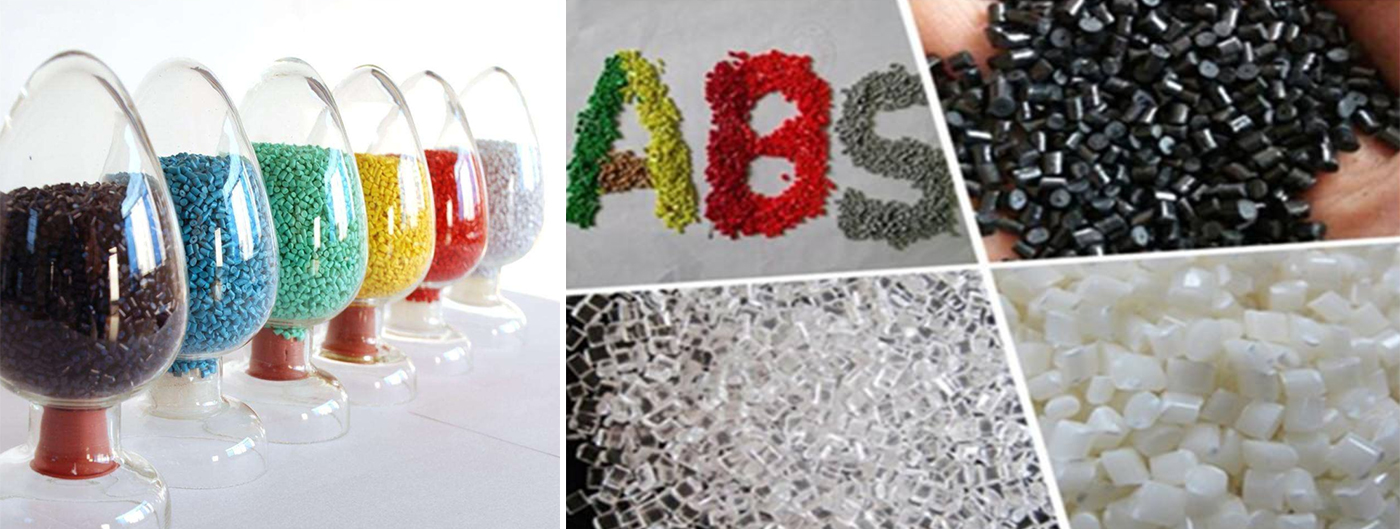

The following are some most commonly used resin materials:

ABS

ABS (acrylonitrile-butadiene-styrene) is more widely used in various industries from automotive to pipeline manufacturing because of its most remarkable impact force and mechanical strength. Metallic coating is most easily attached to ABS, So this material is very suitable for the productions of telephone, shower head and handled products. However, This material is not very resistant to chemicals, so it is better not to use it in applications require electrical insulation or ultraviolet resistance.

Acetal/POM

POM, also known as Acetal, boasts outstanding surface lubricity, resistance to creep (memory) and chemical solvents. It is an ideal material for applications in the food, beverage, mechanical, automotive and household industries. We usually choose this resin to manufacture toy components, as well as gears and bearings. Besides, it is often applied in production of automotive and household products. However, it is not a good choice for applications under high temperature conditions.

Polypropylene

Polypropylene, commonly known as PP, is renowned for its flexibility in packaging, fluid management and processing, household products and some automotive parts. Although polypropylene is a kind of flammable material and vulnerable to ultraviolet radiation, It still has good chemical resistance and electrical resistance. Most grades of PP are flammable and susceptible to degradation by UV radiation.

HIPS

HIPS, Short for high impacting polystyrene, is a hard material with a low cost performance cost performance and customizable surface. This material is easy to print, glue, gluing and decoration, and is commoner in business, Display, printing, graphic and prototype industries. Although it is flammable, There are flame retardant varieties on the market.

LDPE

LDPE, i.e. Low-Density Polyethylene, is the version of polyethylene with the highest flexibility. It has strong moisture resistances and high impacted strength. This material is usually used in the production of many consumer goods, Household goods, as well as medical supplies and wires. However, This material is difficult to bond, so it is better not to use it in extreme weather or high temperature.

Key Considerations for Selection of Resin Materials:

Keep the following variables in mind when choosing a resin material for your production project:

· Impact Strength ‿Some plastic product requires a higher base strength than the rest of them, so the IZOD impact strength of a resin material should be decided before you start the mold.

· Tensile Strength ‿We usually use ultimate tensile or ultimate strength to measure a resin's tension resistance and its capability to withstand a certain amount of load.

· Flexural Modulus ‿how much a material can be bent without being damaged and is still able to return to the original shape.

· Heat Resistance ‿Some plastic products that requires insulation or tolerance for a relatively wider range of temperature conditions, the heat resistance is very important.

· Water Absorption ‿how much water is absorbed by a material after 24 hours of immersion, usually measured in percentage.

Selection of Resin Materials for Your Project

If you choose the most appropriate resin material before you start the mold, you will not only save time and cost, but also ensure your production with the highest possible level of performance and manufacturability. To guarante the ideal resin material choice, we suggest you to consult with a qualified plastic injection molding company (Best times mould & plastic products technology Ltd.)